Framo Morat

Since the parent company was founded in Eisenbach, Germany in 1863 by Johann Morat, the wheel hasn't been reinvented but the technology of drives and gears has been continuously improved. With a world-wide distribution network of sales representatives, Framo is a global producer of high-grade drive solutions for many industrial branches. The core competence of the company is the production of gears and in particular worm gears, with Framo-Morat ranking among the leading suppliers in Europe.

More recently, Framo has evolved into a consulting company and has unique capabilities in fully automated production and engineering.

With an extensive knowledge base, Framo has the ability to manage the entire development process from concept through engineering & design to manufacturing, testing, assembly and production. Our customers trust us to design the product according to their requirements and they have found that they benefit more, the earlier Framo is involved in the process. In summary, Framo's wide range of product offerings and services enable us to bring together all the disciplines to ensure a successful product life cycle.

To deliver the variety of products competently Framo is divided into three distinct organizations:

Gears

Framo's advanced machining facilities coupled with our extensive knowledge base allows us to offer competent solutions for complex machining tasks. Our capabilities range from the manufacture of raw parts to soft machining, hardening and hard machining, all from a single source. We can provide external and internal spur gears, helical and spherical gears to a customer's specifications.

Worm Gears

Framo offers a standard line of worm gears and is the market leader in worm gears with more than 40 million worm gear sets sold world-wide in over 40 years. In addition, we can provide customized solutions. Framo's custom capabilities in worm gears include the design and production of gears fabricated from steel, bronze, phenolic or plastic in diameters of 20 to 250 mm with center-to-center distances of 17 to 125 mm.

Drive Systems

Framo's drive system division includes slip-on geared motors, linear actuators and push-pull chains. Based on modular design principles, all drives are customized to the individual application of the customer.

Framo also offers drive solutions that are designed and manufactured entirely to customers' requirements. For this purpose Framo has a prototype department which manufactures and tests the custom drives in small quantities. This approach allows us to optimize custom drives for volume production.

Our gears and worm gears are primarily delivered to manufacturers of gear boxes and gear motors in the machine building industry as well as printing and textile machine industries.

Rapidly growing markets for our drive systems include the printing industry, tool making, stage and light engineering, as well as materials handling and rehabilitation devices technology.

Ensuring a company's success in a rapidly changing environment requires the ongoing training and continual evolution of its employees. The competitiveness of mature companies depends more than ever on the personal qualifications and the motivation and the willingness to perform of each individual. That's why professional training is likewise an important element of Framo's philosophy. On any given day, 10-20 trainees are receiving an education as industrial clerks, machine fitters, machine operators or mechatronic technicians.

In brief

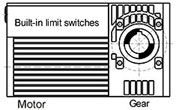

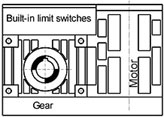

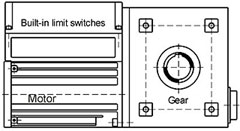

Compacta slip-on geared motors with integrated limit switches are ideal drives for reversing tasks.

The compact dimensions and light weight are achieved by using a spur and worm gear transmission, combined with performance-optimized motors. Compactas are particularly suitable for applications where space is limited.

Benefits at a glance:

- integrated mechanical or electrical limit switches

- low noise level

- lightweight construction

- explosion-proof in accordance with ATEX 95

- splash-water (IP65)

- can be customized

MR 6

Output speed: 2,9 - 100 min-1

Output torque: 10,5 - 60 Nm

Transmission ratio: 27 - 450:1

MS 12

Output speed: 3 - 193 min-1

Output torque: 12 - 142 Nm

Transmission ratio: 14,2 - 225:1

MR 30

Output speed: 2,6 - 123,4 min-1

Output torque: 60 - 300 Nm

Transmission ratio: 22,7 - 264,6:1

AG 60

Output speed: 0,9 - 124 min-1

Output torque: 60 - 600 Nm

Transmission ratio: 22,5 - 732,4:1

What makes a FRAMO slip on gear motor different from an ordinary gear motor?

- Through the use of aluminium technology and special gear materials, the weight and the space required for the gear motor can be reduced by up to 50%.

- The small dimensions yield a high power density.

- Multiple options such as :

- Limit switch stop with or without reversing contactor control,

- Brake,

- Potentiometer,

- Encoder,

- etc.,

enables the user to lay out a complete drive system. You no longer need to perform additional design, procurement and installation of limit switches, measurement systems etc., which means that your time to market are both substantially reduced.

Framo slip on gear motors are noted for their excellent smooth running. Using the renowned FRAMO worm gear sets, as well as fitting noise-reducing gear wheels in conjunction with an encapsulated motor, reduces the running noise to a minimum.

Compacta Drives for pool covers

We have designed gear motors based on the Compacta concept specifically for pool cover drives. These gear motors use 24 V DC and deliver a torque of between 60 and 500 Nm.

In brief

LiMax - the slim all-cylindrical Linear actuator with Maximum force rating and a modular design uses an in-line layout of motor, planetary gearing and lead screw drive (or ball screw) to achieve a high force rating in relation to the diameter of the body. The wide range of options lets you choose specifications to suit most applications.

The integrated stroke limit switches are fully adjustable, allowing on-site adjustment to suit the application.

The LiMax is a very cost-effective linear actuator offering the optimum price/performance ratio.

Benefits at a glance:

- Integrated fully adjustable limit switches with optional safety switch

- Splash-proof (IP65) option

- Stainless steel resists corrosion

- Customized versions to order

- Special stroke lengths available on request

- Stroke force of up to 3000 N

- Stroke speed of up to 31 mm/s

- Standard stroke lengths of up to 400 mm

- Stroke force of up to 5000 N

- Stroke speed of up to 84 mm/s

- Standard stroke lengths of up to 800 mm

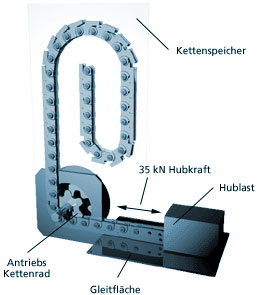

In brief

The LinearChain is able to move loads horizontally and vertically.

The LinearChain is made of specially formed links, whose geometry prevents the chain from buckling under load. This allows the LinearChain to work like a conventional linear actuator.

Benefits at a glance:

- Ideal for realizing long strokes, especially for applications where space is limited

- Compact storage, also in multi-axis applications

- Constant, shock-free motion

- Synchronous operation for horizontal or vertical motion

LinearChain With 25mm Pitch

Type 25PS

Stroke force of up to 3.000 N

Type 25PSG

Stroke force of up to 3.000 N

LinearChain With 40mm Pitch

Type 40PS

Stroke force of up to 8.000 N

Type 40PSG

Stroke force of up to 8.000 N

Type 40PSR

Stroke force of up to 12.000 N

LinearChain With 60mm Pitch

Type 60PS

Stroke force of up to 18.000 N

Type 60PSG

Stroke force of up to 18.000 N

Type 60PSR

Stroke force of up to 25.000 N

Type 60PD

Stroke force of up to 35.000 N

Type 60PDG

Stroke force of up to 35.000 N

General Information About The LinearChain

Users can choose from a number of different systems for linear motion applications in industrial equipment. These generally involve hydraulic/pneumatic cylinders or electro-mechanical lead and ball screw drives.

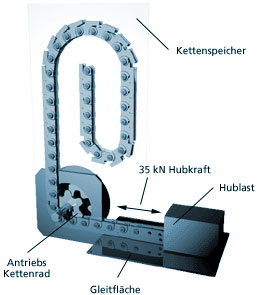

The Framo Pushpull Chain represents an impressive new development of a simple principle.

It is a special kind of chain which, unlike the conventional mechanism, becomes rigid when operated under thrust load, but can still be looped and driven by a conventional sprocket wheel (see Fig.1). The Framo Pushpull Chain can realize thrust forces of up to 35 kN.

(fig. 1)

(fig. 2)

The chains are given their push force characteristics by incorporating specially shaped side links that engage and support each other with very little axial play (see Fig. 3).

(fig. 3)

The load is attached to the end of the chain, for example, with bolts or any preferred arrangement, such as a latching mechanism or trunnion using the mounting holes provided.

The other, free end of the chain can be guided to individual requirements. To keep the space required to a minimum, it is generally rolled up in a storage facility (see Fig. 2). The ease with which the overall length can be minimized is one of the main advantages of the Framo "Push-Pull Chain" system.

(fig. 3)

Examples for LinearChain Storage Geometry

The main applications for LinearChains are in effecting the push-pull movement of large and medium-sized loads in any direction (including vertical movement). The chain sprocket can be driven by a gear motor, or if preferred a hydraulic motor.

Depending on the pushing force, length and travel speed required, the LinearChain can be configured to run on a given sliding surface, or a special guide channel can also be supplied if preferred.

Standard chain sizes with 25, 40, and 60 mm pitch are kept in stock, ensuring that an optimum solution can be offered on short deliveries.

Special hardened steel is generally used for the chain links (and there is also the option of stainless or annealed steel).

In briefThe DiscPower is a dynamic, brushless and maintenance-free synchronous-disc motor with integrated, quiet running, low backlash planetary gear.

It is suitable for typical servo motor applications and offers a shorter total length.

Benefits at a glance:

- Minimum space requirement

- Cost-effective, maintenance-free, brushless motor with integrated planetary gear

- Low noise level through innovative gear technology.

| Type Motor power [kW] | Motor speed [min-1] | Transmission* Output speed [min-1] | Output torque (100% duty cycle) [Nm] | Max. torque (S2) [Nm] | ||

| DP 080 A | 0,42 - 0,55 | 3000 / 4500 | (5:1), 10:1, 15:1, 25:1 | 120 - 600 (900) | max. 40 | max. 100 |

| DP 080 | 0,73 - 1,03** | 3000 / 4500 | 10:1, 15:1, 25:1 | 120 - 600 (900) | max. 65 | max. 100 |

Power depends on voltage.

The motors can operate using 24 V - 48 V battery-voltage or using 110 V - 400 V.

The exact data will need to be calculated depending on custom specifications.

* more transmissions on request.

** The permissable duty cycle depends on ventilation.

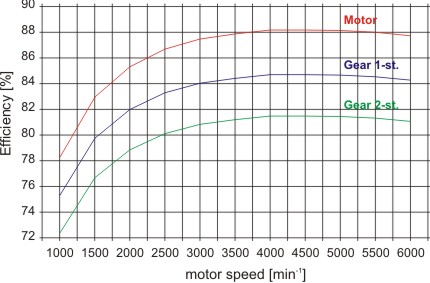

Synchronous disc motor, Type DP Efficiency as function of motor speed